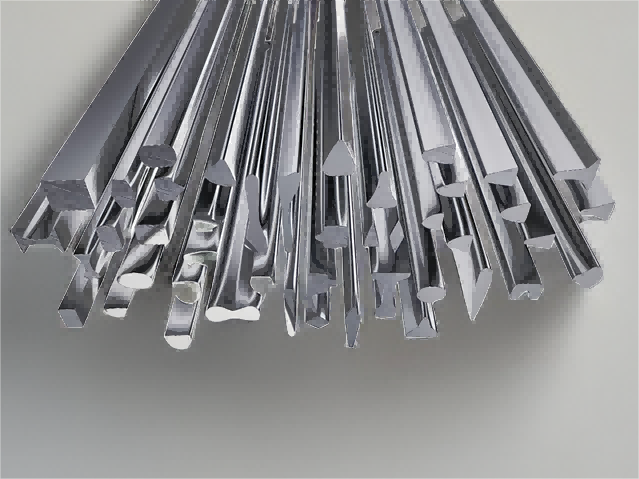

Flatline Wire

Profile Wire Shaped Flatline Wire Manufacturers Cold Rolled High Toughness

MTSCO, a wire manufacturer specializing in Flatline Wire, has 17 years of experience in supplying steel wire, complete production technology, and extensive management experience.MTSCO Flatline Wire is renowned for the elegance of its flat shapes and its wide range of applications in stainless steel, carbon steel, nickel alloys as well as oil-tempered steel. Used in a wide range of applications in the electronics, aerospace, and automotive industries, Flatline Wire is highly regarded for its high strength, excellent heat, and corrosion resistance.

Shaped Wire Flatline Wire Manufacturers Cold Rolled High Toughness

Product name: Shaped Wire Flatline Wire

Use: Clutch spring, piano wire, valve spring, etc.

Diameter: φ1.8mm -φ16mm

Advantageous features of Flatline Wire:

1. High Strength: Its special shape gives it greater strength and stability when subjected to high pressure, making it suitable for high-pressure environments.

2. High abrasion resistance: the flat shape reduces the area of the wire in contact with other objects, reducing wear and prolonging its service life.

3. Versatile sizes: Flatline Wire offers a wide range of width and thickness options to meet diverse design needs.

4. Precise Positioning: Due to its flat shape, it provides excellent alignment and positioning capabilities, which are critical for precision assembly and construction.

5. High efficiency: Compared with round wires, flat wires can save more space when packing and transporting, thus improving efficiency.

Flatline Wire Application Areas:

1. Electronics industry: used in miniature electronic devices, connectors, and sensors as highly efficient conductive wires.

2. Automotive industry: for sensors and electronic components in automobiles to ensure accurate and stable signal transmission.

3. Solar energy field: used as connecting wires for solar panels, providing efficient current transmission and stability.

4. Communication equipment: used for high-frequency signal transmission, providing high speed and stable data flow for communication equipment.

5. Precision machinery: used as key components in a variety of high-precision machinery and equipment to ensure their durability and stable operation.

Quality Assurance:

Initial Stage: Verification of Material Test Certificates (PMI), Evaluation of Tensile Strength, Examination of Surface/Dimensions

During Manufacturing: Designated personnel oversee and validate in alignment with the production process chart, retaining a duplicate for records.

Pre-Dispatch: Assessment of Mechanical Attributes, Review of Surface/Dimensions, or as stipulated by the client's specifications.

Company Overview:

MTSCO stands as a leading purveyor of steel wire, backed by advanced manufacturing technology and an extensive management portfolio. Our product range encompasses spring wire, shaped wire, nickel alloy wire, welding wire, electrolytically polished wire, fine wire, netting wire, hose wire, cold forging wire, security wire, and many more. We primarily utilize materials such as stainless steel, nickel alloy, and alloy steel sourced from some of the most reputable steel producers in China. Our offerings span a size range of 0.15 mm to 16 mm in diameter. Housing state-of-the-art equipment, our factory ensures all products meet or exceed ASTM, DIN, GTB, JIS, JSG, and other global standards. Our skilled international trade team is committed to providing exceptional service and is adept at tailoring products to meet specific client needs.

English

English Español

Español Русский

Русский عربي

عربي