MTSCO undertook a critical supply mission for Petrobras's FPSO P80/P83 deepwater oil and gas platform: the delivery of 1,500 tons of 2507/2205 duplex steel fittings and flanges within a 60-day window. Key Achievements & AdvantagesSuccessfully delivered 1,500 ......

Read MoreMetal corrosion refers to the destruction of metals caused by the chemical action of environmental media, combined with physical, mechanical, or biological factors.The damage of materials or structures caused by chemical or electrochemical reactions under atmo......

Read More——Learn about the wide range of applications Welded wire is widely used in construction, agriculture, and manufacturing for reinforcement, fencing, and structural support. Learn its key applications, benefits, and how to choose the right type. Welded wire ......

Read More——Understanding the Most Popular Welding Wire for Different Applications Stainless steel welding wire is the most commonly used due to its corrosion resistance, durability, and aesthetic appeal, making it ideal for marine, food processing, and structural ap......

Read More——Choosing the Right Wire Diameter Selecting between 0.8 mm and 0.9 mm MIG wire impacts weld quality, penetration, and efficiency. Learn how to choose the best wire for your welding needs. Metal Inert Gas (MIG) welding is one of the most commonly used weld......

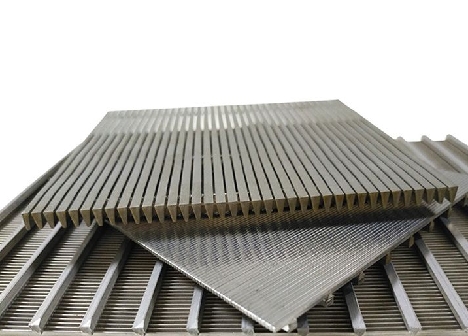

Read MoreProfile Wire Screen is widely used across many industries and is an essential material in filtration scenarios. Below is a detailed introduction to Profile Wire Screen.Definition of Profile Wire ScreenProfile Wire Screen is a type of screen made from specially......

Read More——Types, Applications, and Performance Insights for Efficient Welding SolutionsWelding wire is a crucial material in the welding process, widely used in various industries such as automotive, energy, and aerospace. This article introduces the types and chara......

Read More——Choosing the Right Welding Wire for Optimal Performance Selecting the appropriate welding wire is crucial for enhancing weld strength and corrosion resistance across various industries. This guide explores different types of welding wire, material options......

Read More--Understanding Varieties, Sizes, and Applications of Profile WireProfile Wire is essential in industries like water treatment, mining, and oil and gas, designed for efficient screening and filtration. It comes in various sizes and materials, providing tailore......

Read More---Versatile Solutions for Diverse Industrial Needs Profile Wire, crafted from stainless steel, nickel alloys, or cobalt alloys, offers exceptional strength and adaptability for various applications, including water treatment, construction, and agriculture, m......

Read MoreStainless Steel Spring Wire - Classification, Characteristics, and Applications Discover the types, characteristics, and applications of stainless steel spring wire. Learn how to select the right wire based on corrosion resistance, mechanical performance, fat......

Read MoreCharacteristics of Spring WireHigh Wear ResistanceDuring furniture usage, the spring system, particularly in sofas and mattresses, is subject to frequent compression and release, leading to wear. To maintain good elasticity in furniture, high wear-resistant sp......

Read More

English

English Español

Español Русский

Русский عربي

عربي