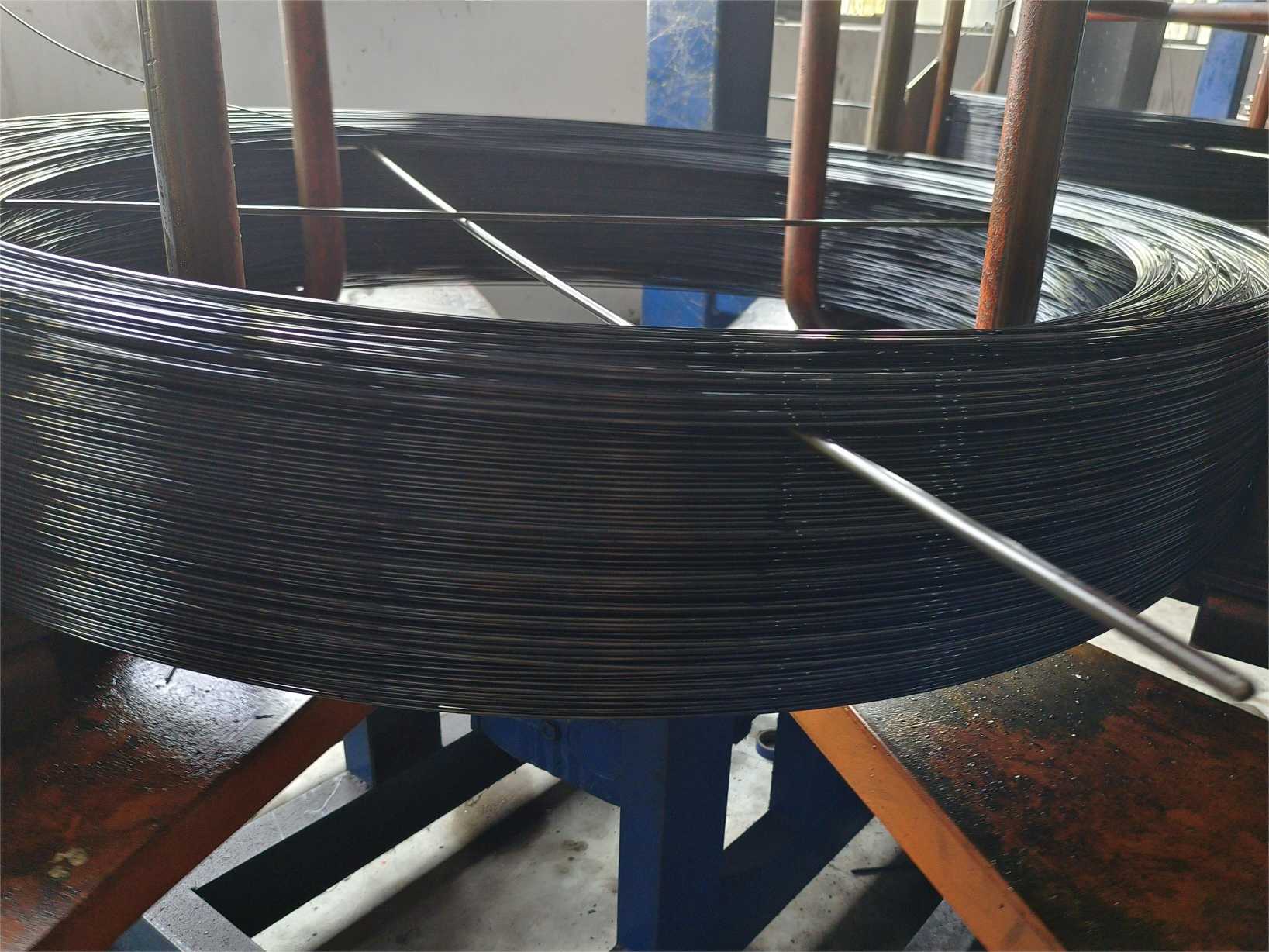

Oil Tempered Spring Wire

ASTM A401 9254 / 9254V Oil Quenched-tempered Spring Wire Manufacturer

9254 and 9254V oil hardened spring wire is a class of high quality spring materials with excellent elasticity and fatigue resistance. They are widely used in automotive manufacturing, mechanical engineering, aerospace and other fields for the manufacture of demanding spring components and mechanical parts, such as high-performance automotive suspension systems or aircraft engine springs. 9254 spring wire has excellent toughness and corrosion resistance and is suitable for high-load and high-precision spring products. And 9254V spring wire is micro-alloyed from 9254 to further increase strength and fatigue life for spring applications in special environments.

ASTM A401 9254 / 9254V Oil Quenched-tempered Spring Wire Manufacturer

Features :

1. High strength: 9254 / 9254V spring wire can withstand high pressure and heavy loads.

2. good resilience: after oil hardening, the wire maintains excellent resilience, ensuring stable performance over long periods of time.

3. Excellent fatigue resistance: 9254 / 9254V spring wire exhibits excellent fatigue resistance under high frequency vibration or cyclic loading, extending spring life.

4. Excellent corrosion resistance: Suitable for use in wet or corrosive environments, ensuring long term stability.

5. precise dimensional control.

6. Customisability.

Application Areas:

1. automotive manufacturing: widely used in automotive suspension systems, seat springs, fuel injectors and sensors, etc. to ensure automotive performance and comfort.

2. Mechanical Manufacturing: In mechanical equipment, this spring wire can be used in torsion springs, tension springs, closed springs and many other spring types to provide reliable mechanical support.

3. Furniture Manufacturing: Used in furniture for bed springs, sofa springs, etc. to provide comfortable elastic support for furniture.

4. Electrical and electronic products: 9254 / 9254V spring wire in electrical and electronic products can be used in switch springs, connectors, contacts, etc., to ensure the stability of electrical equipment.

5. Industrial equipment: used in various types of industrial equipment such as torsion springs, tension springs, tension springs, etc. to meet the needs of different industrial applications.

6. Other fields: can also be used in medical equipment, aerospace, energy and other fields, to meet the high performance requirements of springs in different fields.

Quality Control:

Quality Control

Why Choose MTSCO?

Factory Complex

Provide you with cost-effective products and professional services.

One stop procurement of wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 18 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.

English

English Español

Español Русский

Русский عربي

عربي