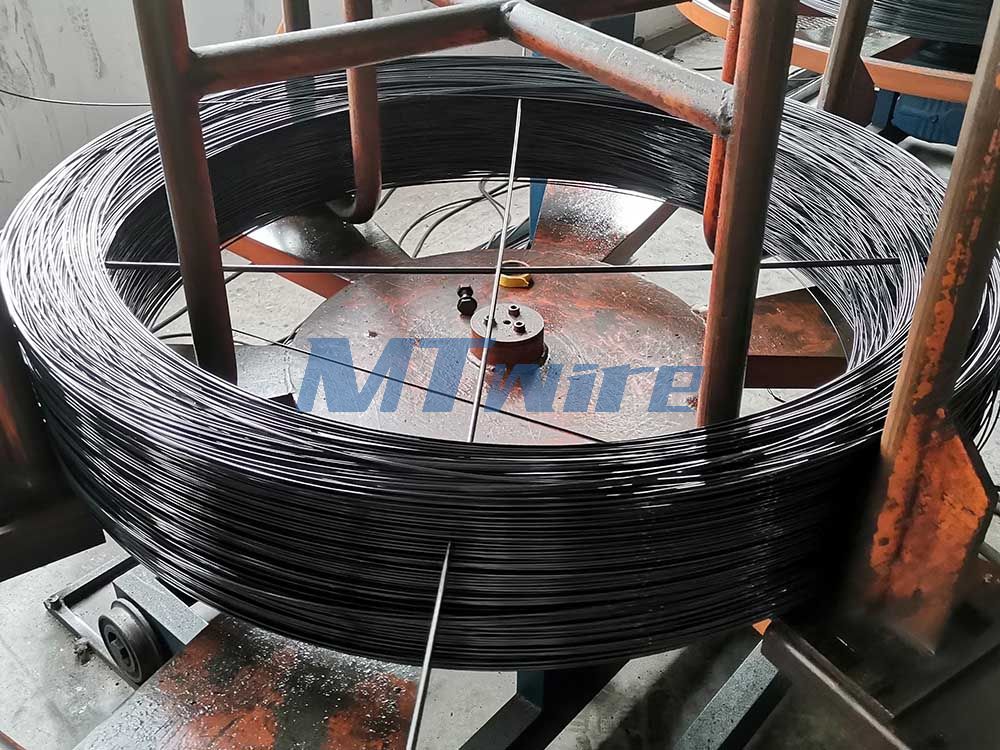

Oil Tempered Spring Wire

ASTM A229 / EN 10270-2 55CrSi Oil Tempered Spring Wire For Machinery Manufacturing

55CrSi Oil Tempered Spring Wire An exceptional spring steel wire with superior elasticity and fatigue properties to bring your projects and applications to life. It is widely used in automotive suspension, industrial machinery, electronic equipment and household appliances. Its high strength and corrosion resistance make it ideal for high-load, high-precision spring components.

ASTM A229 / EN 10270-2 55CrSi Oil Tempered Spring Wire For Machinery Manufacturing

Features of 55CrSi Oil Tempered Spring Wire:

1. high strength: excellent tensile strength, suitable for high load spring components.

2. excellent fatigue properties: durable, long term elasticity and long service life. 3. good shape memory.

3. good shape memory: under repeated loads, the original shape can be restored to maintain stability. 4. corrosion resistance: with excellent tensile strength, suitable for high load spring components.

4. Corrosion resistance: suitable for harsh environmental conditions. 5.

5. High temperature stability: suitable for high temperature applications.

6. Precise Diameter Control: Ensure the stability of precision applications.

7. Excellent surface treatment: clean surface, reduce friction and improve motion efficiency.

Application:

55CrSi Oil Tempered Spring Wire plays a key role in a number of fields. Its high strength and corrosion resistance make it ideal for many projects and applications. The following are some of the application areas:

1. automotive industry: used in the manufacture of spring components for automotive suspension and braking systems.

2. industrial machinery: spring components used in industrial equipment and machinery such as compressors, pumps, valves, etc.

3. electronic equipment: spring connectors and conductive springs used in the manufacture of electronic products.

4. household appliances: spring components for household appliances, such as washing machines, air conditioners, etc.

5. construction and building materials: spring applications used in construction and building materials.

|  |

Quality Control

Before shipment: Mechanical properties test, Surface/Dimension inspection, or according to customers’ requirement

Quality control of raw materials

Factory advantages:

Quality Control

Why Choose MTSCO?

Factory Complex

Provide you with cost-effective products and professional services.

One stop procurement of wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 18 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.

English

English Español

Español Русский

Русский عربي

عربي