50CrV Oil Tempered Spring Wire, is a high-strength spring wire material that is oil hardened to obtain excellent mechanical properties and elasticity. Its characteristics include high hardness, high fatigue resistance, excellent resilience and good corrosion resistance, which makes it widely used in various spring applications, such as automotive manufacturing, home appliance industry, construction engineering or machinery manufacturing, etc. 50CrV Oil Tempered Spring Wire provides stable elastic support and excellent performance.

ASTM A229 50CrV Oil Tempered Spring Wire For Automotive Industry

Mtsco is a professional supplier of steel wire with 17 years of experience, complete production technology, and extensive management experience. Mtsco is dedicated to specializing in spring steel wire, nickel alloy wire, welding wire, and shaped wire. In addition, we can supply electro-polishing quality wire, mesh wire, annealed wire, cold heading wire, locking wire, etc. The main materials are nickel alloy, stainless steel, carbon steel, and alloy steel. Our products are widely used in the automotive and machinery fields, petrochemical, pipeline, valve, pressure vessel, power plant, chemical equipment field, nuclear power field, communication and electronic machinery field, etc.

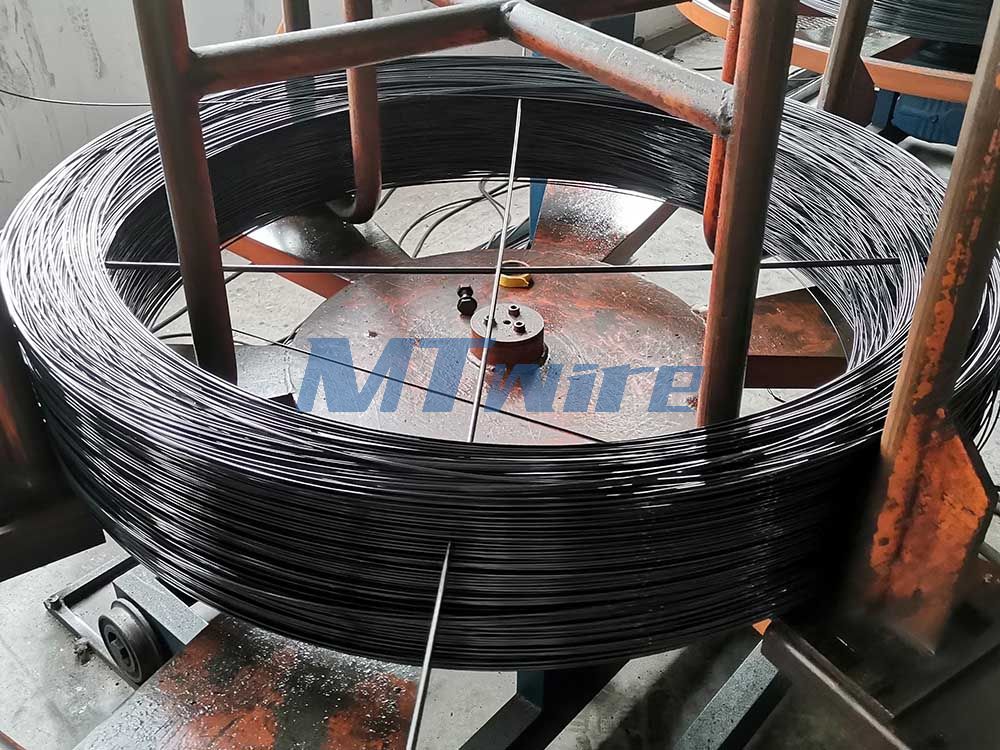

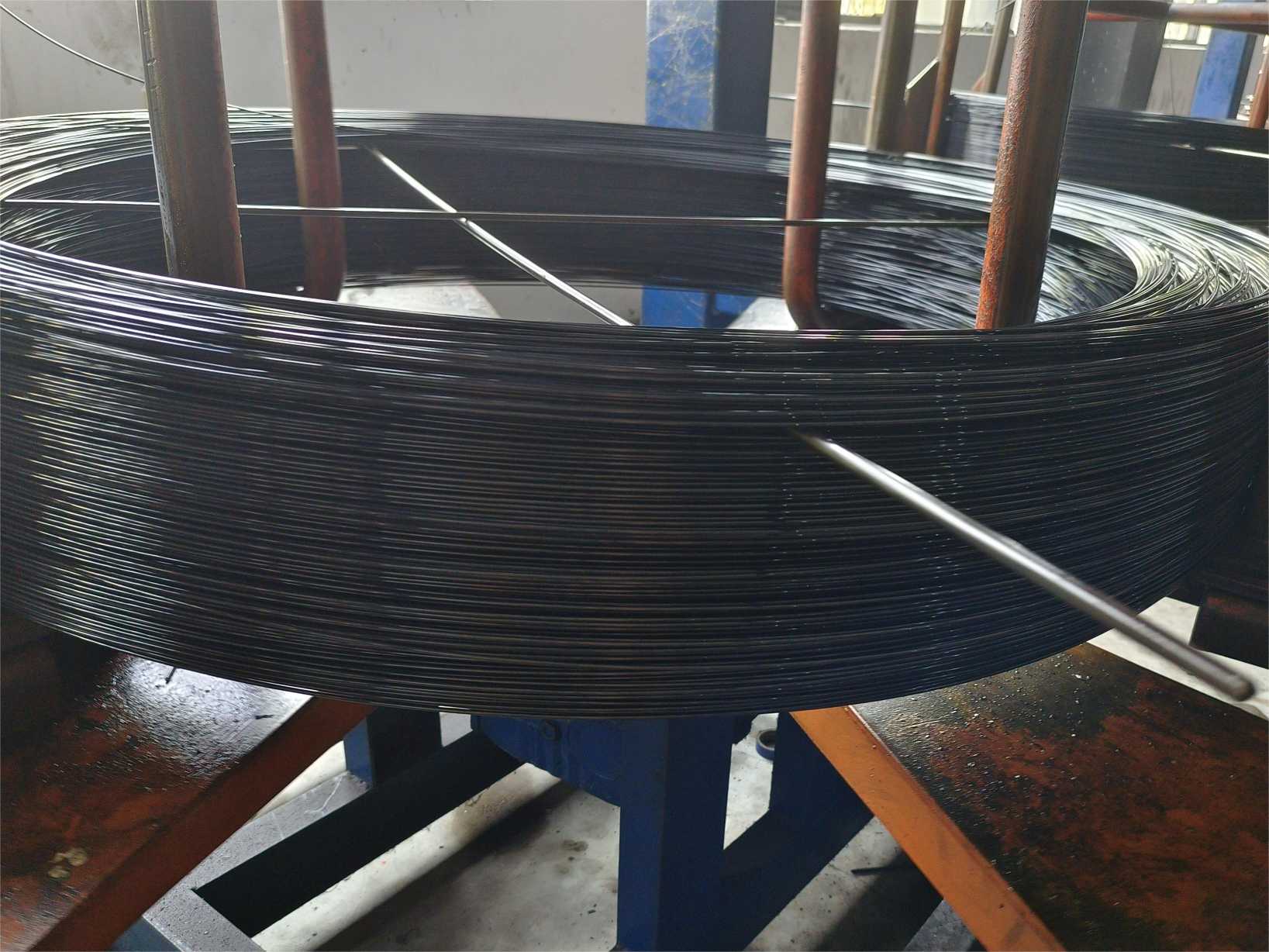

Product Name: Oil Quenched-tempered Spring Steel Wire

Material: 55CrSi, 50CrV, 9254, 9254V, 60SiZMn,etc.

Use: Clutch spring, suspension spring, valve spring, etc.

Standard: ASTM A229 / A401 / A1000 / A 877, EN 10270-2, etc.

Diameter: φ1.8mm -φ16mm

Cross Section: Special-shaped steel bars with circular and various non-circular sections

Features:

1. High Strength: After oil hardening treatment, the spring wire has excellent strength and is able to withstand heavy loads and high pressures and maintain long term stability.

2. Excellent elasticity: Spring wire has good resilience, even after a long period of use, it can return to its original shape, maintaining its elasticity and stability.

3. Durability: Excellent corrosion and abrasion resistance, suitable for a variety of harsh environments and high-frequency use scenarios.

4. Stability: Through precise production processes, the dimensions and properties of the spring wire are stable and reliable, ensuring consistent performance in different applications.

Application:

1. Automotive industry: used in automotive suspension systems, brake systems, seat springs, etc.

2. Electrical appliances and home appliances: used in spring components of electric fans, air conditioners, washing machines, and other home appliances.

3. Machinery manufacturing: widely used in various types of mechanical equipment, elastic components, connectors, and shock-absorbing components, to improve mechanical properties and stability.

4. Construction engineering: used in the building structure of anti-vibration support and vibration-damping devices.

5. Aerospace: It is used in various spring components of aerospace equipment such as aircraft and satellites to ensure flight safety and stable performance.

Factory advantages:

We have 7 advanced electric furnace production lines, and the rolling is up and down synchronization

20000 tons annual capacity, wire OD range is 0.15-16mm, and covers the most materials

Raw materials come from well-known factories with guaranteed quality

The staff are skilled in operation, adjust the mold and pull line once, and the yield is high

Strict quality inspection, four quality inspections from online to offline

Strict compliance with international standards such as ASTM, DIN, GTB, JIS, JSG, etc. We can also customize shaped and non-standard wires according to customer requirements.

English

English Español

Español Русский

Русский عربي

عربي