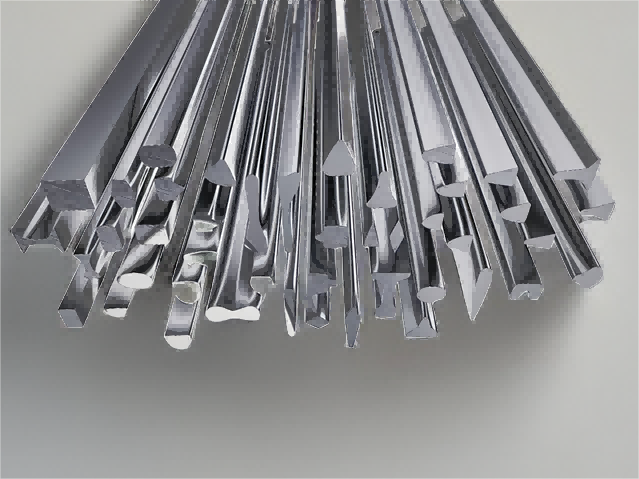

Wedge Wire/Screen

Stainless Steel Keystone Wedge Wire For Water Treatment Screening Equipment

MTSCO, a trusted supplier of Stainless Steel Wedge Wire. In our 17 years of experience in supplying steel wire, complete production technology and extensive management experience, our pursuit of innovation and quality never changes.MTSCO Stainless Steel Wedge Wire, with its excellent corrosion resistance and high temperature performance, always meets your demanding needs. It is an ideal choice to ensure stability and durability in any application environment.

Stainless Steel Keystone Wedge Wire For Water Treatment Screening Equipment

| Type | Shaped Wire |

| Material | Nickel Alloy, Stainless Steel, Carbon Steel, Alloy Steel |

| Standard | ASTM A580, ASTM A510, ASTM A853, ASTM A229, JIS G4309, EN 10088-3, EN 10270-2, GB/T4240, ASTM B166, ASTM B472, ASTM B564, etc. |

| Size | φ0.15mm-φ16mm; Or According To Customers' Requests |

| Surface | Bright, matte ,downy, electrolysis bright ,cloudy ,plain ,black,etc |

| Packing | Woven bag, core, wooden reel, etc |

Features of Stainless Steel Wedge Wire:

1. Corrosion resistance: Stainless steel material brings excellent corrosion resistance, suitable for a variety of harsh environments.

2. High strength: the wedge design enhances the structural strength of the wire to meet the high pressure requirements.

3. Temperature stability: it can maintain stable mechanical properties in high temperature environment.

4. Easy to clean: Fine surface treatment, easy and convenient to clean.

5. Wear-resistant: Stainless steel has high hardness and strong wear resistance.

Stainless Steel Wedge Wire Application Areas:

1. Screening equipment: Stainless Steel Wedge Wire is corrosion and abrasion resistant, and is often used in screening equipment, such as sieve plates in water treatment equipment.

2. Petrochemical industry: Stainless Steel Wedge Wire is resistant to high temperature and pressure, and is widely used in filtration and separation processes.

3. Construction field: The shape and strength of Stainless Steel Wedge Wire make it widely used in the construction field as well, such as in the production of decorative panels and parapets.

4. Food and Beverage Industry: Due to its non-susceptibility to chemical corrosion and bio-adhesion, Stainless Steel Wedge Wire is commonly used in filtration and screening processes in the food and beverage industry.

5. Environmental protection field: It is often used in environmental protection projects such as sewage treatment or solid waste treatment to reduce pollution.

Standard Wire surface:

Extra Clean: Extra clean is also referred to as “bright annealed” or “bright annealed and cold rolled”

Grease (only round wire): Drawn in a heavy grease produces an “Ultra bright” surface for decoration

Soap (only round wire): Soap is used as a lubricant in the drawing process and is not removed. It can act as a lubricant during part forming. A soap surface is available in tempered products.

Plated: Many plating options are available.

Special surface: Handle according to your needs

Quality Control:

Raw Materials: MTC checking(PMI), Tensile strength test, Surface/Dimension inspection

Production: Specially assigned person shall follow up and check according to the process flow card, and finally keep the copy

Before shipment: Mechanical properties test, Surface/Dimension inspection, or according to customers’ requirement

Quality control of raw materials:

Slight changes in the chemical composition and mechanical properties of raw materials will have a significant impact on the properties of finished steel wire. Therefore, the quality of the base bar is one of the key factors in determining the quality of finished steel wire. We will strictly test the raw materials. Only raw materials that pass the test and meet the standards can go to the next process.

Company Profile:

MTSCO is a professional supplier of steel wire with complete production technology and rich management experience. We produce spring wire, shaped wire, nickel alloy wire, welding wire, electrolytically polished wire, fine wire, wire for netting, hose wire, cold heading, locking wire, and other products. Our main materials are stainless steel, nickel alloy, and alloy steel, and the raw materials we use are from the biggest and most well-known steel mills in China, We can supply wire in sizes ranging from 0.15 mm to 16 mm in diameter. Our factory is well-equipped and our products conform to ASTM, DIN, GTB, JIS, JSG, and other international standards. We have experienced foreign trade staff with high-quality service and can produce high-quality products according to customers' requirements.

English

English Español

Español Русский

Русский عربي

عربي