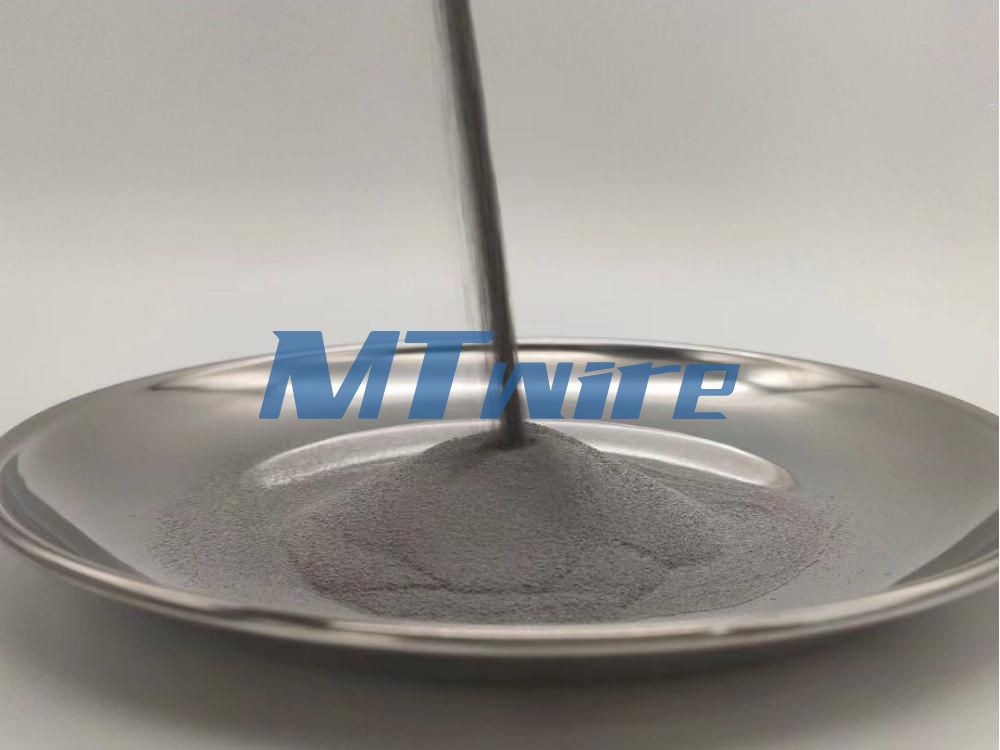

Laser Cladding Powder

Laser Cladding Powders Alloy Powder Thermal Spay Powder Stainless Steel

Alloy powder for laser cladding is generally used for powder welding of smaller parts with good corrosion resistance and excellent mechanical properties, good welding performance, widely used in daily necessities, aviation, aerospace, precision molds and other industrial fields. Our powder can help you produce a smooth and precise surface when welding. Use our reliable laser cladding powder to improve your productivity.

Laser Cladding Powders Alloy Powder Thermal Spay Powder Stainless Steel

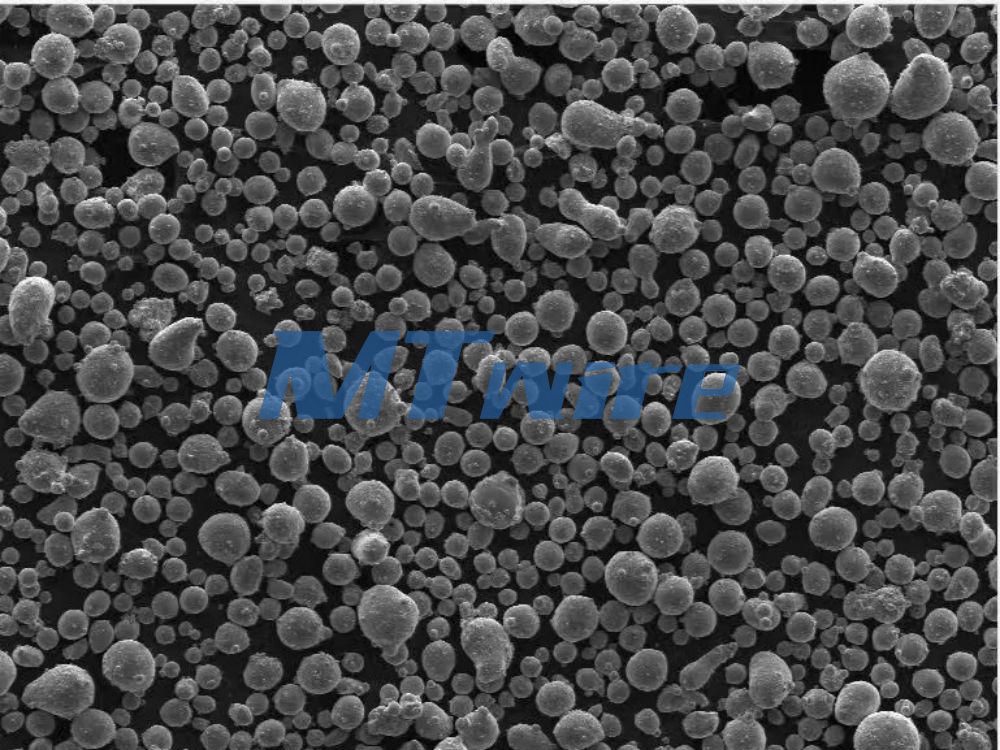

Specification

Material | Melting hardness | General laser/high-speed laser | Performance Profile |

2209 | HRC20 | 53-150um/15-53um | Duplex stainless steel for surface corrosion protection coating |

304L | HRC15-18 | 53-150um/15-53um | Austenitic stainless steel for surface coating for corrosion protection |

316L | HRC15-18 | 53-150um/15-53um | Austenitic stainless steel for surface coating for corrosion protection |

310S | HRC15-18 | 53-150um/15-53um | For anticorrosive coating of surfaces |

420 | HRC45-50 | 53-150um/15-53um | Wear-resistant and corrosion-resistant, salt spray-resistant 1000H, used for piston rods, cylinders, hydraulic rods restoration |

430 | HRC48-53 | 53-150um/15-53um | Hydrogen sulfide gas corrosion resistant shafts |

440 | HRC53-57 | 53-150um/15-53um | Hydrogen sulfide gas corrosion resistant shafts |

KTL105 | HRC50-55 | 53-150um/15-53um | Wear-resistant and corrosion-resistant, used for piston rods, cylinders, hydraulic rods restoration |

KTL108 | HRC50-55 | 53-150um/15-53um | Wear-resistant and corrosion-resistant, used for piston rods, cylinders, hydraulic rods restoration |

17-4PH | HRC38-40 | 53-150um/15-53um | Martensitic stainless steel, corrosion resistance with 304, 430 |

15-5PH | HRC38-40 | 53-150um/15-53um | Martensitic stainless steel, corrosion resistance with 304, 430 |

What is Laser Cladding?

|  |

Advantages

Applications

- Energy Industry: Repair and protect oil, gas, and power equipment.

- Mold Manufacturing: Reduces wear and enhances surface hardness and durability.

- Automotive Manufacturing: Surface repair and modification for transmission systems and engine components.

- Aerospace: Improves wear resistance and corrosion resistance of aircraft components.

- Metallurgy: Enhances the ability of metallurgical equipment to resist high temperatures and corrosion.

- Chemical Industry: Increases the capability of chemical equipment to withstand harsh chemical environments.

- Mechanical Processing: Repairs and modifies the surfaces of mechanical components, improving processing precision and durability.

Quality Control

Why Choose MTSCO?

Factory Complex

Provide you with cost-effective products and professional services.

One stop procurement of wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 18 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.

English

English Español

Español Русский

Русский عربي

عربي