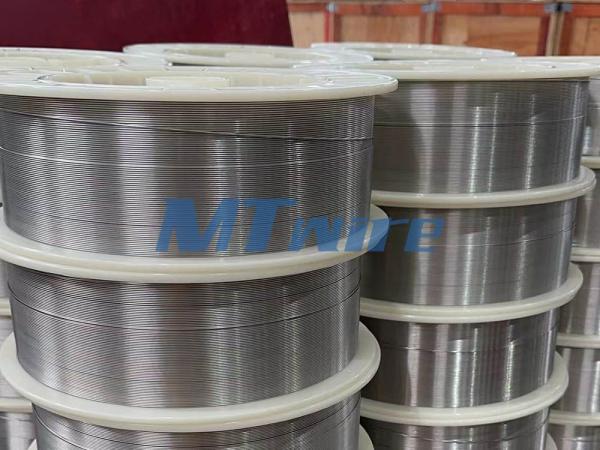

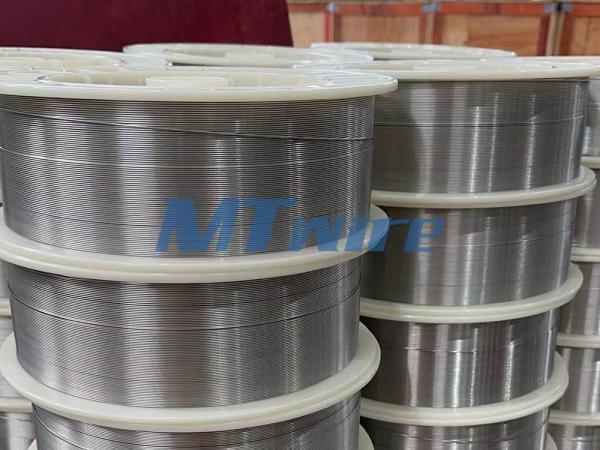

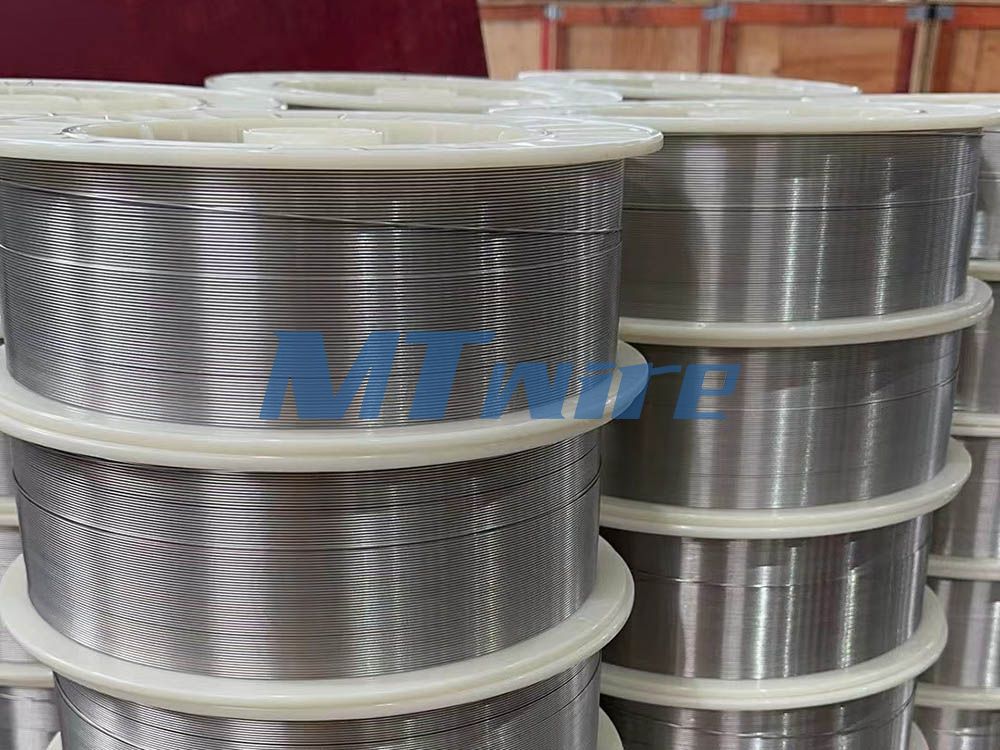

Nickel Alloy Welding Wire

Nickel Alloy ERNiFeCr-1 ER800 Welding Wire in Nuclear energy industry

Nickel Alloy 800 Welding Wire is a high performance nickel-iron based alloy wire with excellent high temperature and corrosion resistance. The wire is suitable for welding needs in petrochemicals, power plants, chemical processing equipment and other high temperature environments. It provides reliable welding performance and excellent mechanical properties for high strength welding and corrosion resistance requirements.

Nickel Alloy ERNiFeCr-1 ER800 Welding Wire in Nuclear energy industry

Nickel Alloy 800 Welding Wire is a high performance nickel-iron based alloy wire with excellent high temperature and corrosion resistance. The wire is suitable for welding needs in petrochemicals, power plants, chemical processing equipment and other high temperature environments. It provides reliable welding performance and excellent mechanical properties for high strength welding and corrosion resistance requirements.

| Ni | Cr | Fe | Mn | C | Cu | Si | S | P | Co | Nb/Cb | Ti | Ta | Al | Mo |

| Alloy 800 | 30-35 | 19-23 | bal | 1.5 | 0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 | - | 0.15-0.6 | - |

| Alloy 800HT | 30-35 | 19-23 | bal | 1.5 | 0.05-0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 | - | 0.15-0.6 | - |

| Alloy 825 | 38-46 | 19.5-23.5 | bal | 1 | 0.05 | 1.5-3.0 | 0.5 | 0.03 | - | 2 | - | 0.6-1.2 | - | 0.2 | - |

Advantageous features of Nickel Alloy 800 Welding Wire:

1. excellent high-temperature stability: the ability to maintain its material properties and strength in extreme high-temperature environments, suitable for welding applications that require heat resistance.

2. excellent corrosion resistance: resistance to corrosive media such as acidic, alkaline and salt solutions, making it suitable for welding in corrosive environments.

3. Excellent Mechanical Properties: Nickel Alloy 800 wire provides high strength, good tensile, yield and ductility properties for applications requiring high strength welding, ensuring reliable welded joints.

4. Accurate welding performance: produces high quality welds with good gas tightness and crack resistance, ensuring the integrity and stability of welded joints.

5. Versatility: Nickel Alloy 800 wire is suitable for a wide range of welding processes, including gas shielded welding, arc welding and plasma welding, to meet different processes and needs.

6. Reliability: The wire undergoes strict quality control to make the welding process more stable and reliable.

Application areas of Nickel Alloy 800 Welding Wire:

1. Petroleum and chemical industry: resistance to high temperatures and corrosive environments, such as refineries, chemical reactors, heat exchangers and pipelines.

2. power plant and nuclear energy industry: for high temperature and corrosive environments, such as boiler pipework in power plants, chimneys and the welding needs of nuclear power stations.

3. Chemical processing equipment: Resistant to chemical corrosion and high temperature conditions, such as for the manufacture and maintenance of chemical processing equipment, tanks and pipelines.

4. heat treatment furnaces and stoves: able to withstand thermal stress in high temperature environments, it is suitable for welding needs of high temperature equipment such as heat treatment furnaces, stoves and furnaces.

5. aerospace industry: it can withstand high temperatures and corrosive environments and is used in the manufacture of aircraft engine components, spacecraft structures and other critical welded connections.

6. Other fields: It is also used in medical equipment, marine engineering, power industry and other fields requiring high temperature and corrosive welding.

Mtsco is a professional steel wire supplier with 17 years of experience, complete production technology and extensive management experience. We have an exclusive manufacturer: XINHANG WIRE. MTSCO has formed a highly strategic partnership with XINHANG WIRE as the only international trading centre of XINHANG WIRE. Mtsco specialises in spring steel wire, nickel alloy wire, welding wire and shaped wire. In addition, we can also supply electropolishing quality wire, wire mesh, annealed wire, cold heading wire, lock wire, etc. The primary materials are nickel alloy, stainless steel, carbon steel and alloy steel. Our products are widely used in automobile and machinery, petrochemical, pipeline, valve, pressure vessel, power plant, chemical equipment, nuclear power, communication and electronic machinery, etc.

English

English Español

Español Русский

Русский عربي

عربي