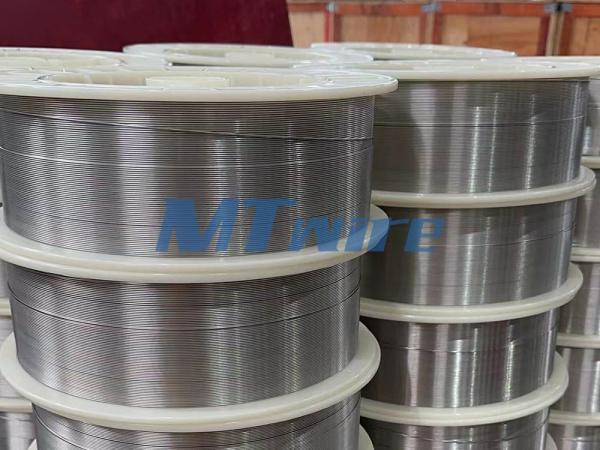

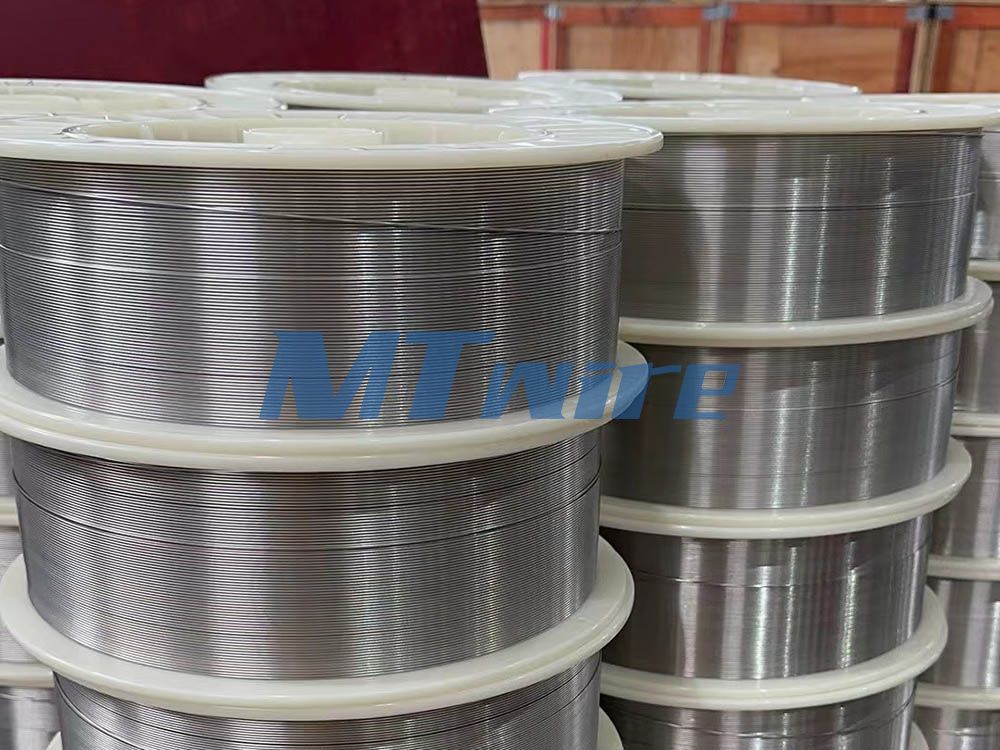

Nickel Alloy Welding Wire

Nickel Alloy Build Up Welding Wire For Boiler Tube Water Cooled Wall Cladding

This nickel alloy welding wire is a versatile product designed for a variety of applications including Cladding, Overlay Welding, Hard Surfacing and Build-Up Welding. Superior corrosion, abrasion and high temperature resistance for boiler tubes, water-cooled wall overlay welding, pressure vessels and other applications, enhancing the durability and corrosion resistance of material surfaces. Whether it's restoring surface hardness to tools, machine parts and structural elements, or complex welding and repair tasks on heavy machinery, pressure vessels and large structures, this nickel alloy welding wire is the ideal choice.

Nickel Alloy Build Up Welding Wire For Boiler Tube Water Cooled Wall Cladding

| Material | Nickel Alloy Wire |

| Grade | Alloy 600, 601, 625, X-750, 718, C2000, C22, C276, C4, X, 400... |

| Standard | ASTM B166/B446/B637/B574/AME4730 |

| Size | φ0.15mm-φ16mm; Or According To Customers' Requests |

| Type | Round, flat, core, braiding, staple |

| Condition | Annealed and Soft, 1/2 hard, 3/4 hard and full hard |

| Packing | Woven bag, core, wooden reel, etc |

Chemical Composition:

| Nickel Alloy | Ni | Cr | Fe | Mn | C | Cu | Si | S | P | Co | Nb/Cb | Ti | Ta | Al | Mo | B | Pb | Bi | Se | W | V |

| Alloy 600 | >=72 | 14-17 | 45087 | 1 | 0.1 | 0.5 | 0.5 | 0.015 | 0.04 | 1 | 1 | 0.5 | 0.05 | 0.35 | - | ||||||

| Alloy 601 | 58-63 | 21-25 | bal | 1 | 0.1 | 1 | 0.5 | 0.015 | - | - | - | - | - | 1-1.7 | - | ||||||

| Alloy 625 | >=58 | 20-23 | 5 | 0.5 | 0.1 | 0.5 | 0.5 | 0.015 | 0.015 | 1 | 3.15-4.15 | 0.4 | 0.05 | 0.4 | 8-10 | ||||||

| Alloy X-750 | >=70 | 14-17 | 5.0-9.0 | 1 | 0.08 | 0.5 | 0.5 | 0.01 | - | 1 | 0.7-1.2 | 2.25-2.75 | 0.05 | 0.4-1.0 | - | ||||||

| Alloy 718 | 50-55 | 17-21 | bal | 0.35 | 0.08 | 0.3 | 0.35 | 0.015 | 0.015 | 1 | 4.75-5.5 | 0.65-1.15 | 0.05 | 0.2-0.8 | 2.8-3.3 | 0.006 | 0.0005 | 3E-05 | 0.003 | ||

| Alloy 800 | 30-35 | 19-23 | bal | 1.5 | 0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 | - | 0.15-0.6 | - | ||||||

| Alloy 800HT | 30-35 | 19-23 | bal | 1.5 | 0.05-0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 | - | 0.15-0.6 | - | ||||||

| Alloy 825 | 38-46 | 19.5-23.5 | bal | 1 | 0.05 | 1.5-3.0 | 0.5 | 0.03 | - | 2 | - | 0.6-1.2 | - | 0.2 | - | ||||||

| Alloy C-4 | bal | 14-18 | 3 | 1 | 0.015 | - | 0.08 | 0.03 | 0.04 | 2 | - | 0.7 | - | - | 14-17 | - | - | - | |||

| Alloy C-22 | bal | 20-22.5 | 44963 | 0.5 | 0.015 | - | 0.08 | 0.02 | 0.02 | 2.5 | - | - | - | - | 12.5-14.5 | - | 2.5-3.5 | 0.35 | |||

| Alloy C-276 | bal | 14.5-16.5 | 45023 | 1 | 0.01 | - | 0.08 | 0.03 | 0.04 | 2.5 | - | - | - | - | 15-17 | - | 3-4.5 | 0.35 | |||

| Alloy C-2000 | bal | 22-24 | 3 | 0.5 | 0.01 | 1.3-1.9 | 0.08 | 0.01 | 0.025 | 2 | - | - | - | 0.5 | - | - | - | - | |||

| Alloy X | bal | 20.5-23 | 17-20 | 1 | 0.05-0.15 | - | 1 | 0.03 | 0.04 | 0.5-2.5 | - | - | - | - | 45148 | 0.01 | 0.2-1.0 | - | |||

| Alloy 400 | 63-70(Ni+Co) | - | 2.5 | 2 | 0.3 | 28-34 | 0.5 | 0.024 | - | 2 | - | - | - | - | - | - |

Nickel Alloy Build Up Welding Wire Advantageous Features:

Nickel Alloy Build-Up Welding Wire Application Areas:

6. Metallurgical industry: used in steelmaking and rolling equipment surface cladding, such as rolls, guide rolls, and so on.

Company Profile:

Quality Control

Why Choose MTSCO?

Factory Complex

Provide you with cost-effective products and professional services.

One stop procurement of wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 18 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.

English

English Español

Español Русский

Русский عربي

عربي