Nickel Alloy Spring Wire

Nickel Alloy 600 Spring Wire with Chemical Processing

MTSCO is a company with high specialization and extensive management knowledge in the field of steel wire supply. We have 17 years of manufacturing experience and our annual production capacity amounts to more than 60,000 tons.

Nickel Alloy 600 Spring Wire with Chemical Processing

MTSCO is a company with high specialization and extensive management knowledge in the field of steel wire supply. We have 17 years of manufacturing experience and our annual production capacity amounts to more than 60,000 tons. We specialize in the production of high quality spring steel wire for the automotive and machinery sectors. In addition, our product line includes a wide range of welding wires, shaped wires, nickel-based alloy wires, braided wires, high-quality wires for electropolishing, mesh wires, annealed wires, cold heading wires, and locking wires. Our main raw material choices include stainless steel, nickel alloys, and alloy steels, which are sourced directly from top Chinese steelmakers such as Baosteel, Yongxing, and Taisteel, etc. MTSCO offers a wide range of product sizes from 0.15 mm to 16 mm in diameter, and we strictly follow international standards such as ASTM, DIN, GTB, JIS, and JSG to ensure the product quality.

Machinability: Although Nickel Alloy 600 is harder than normal stainless steel, it still has good machinability and can be machined into precision spring wire products.

Chemical Composition:

| Chemical Composition: | |||||||||||||||||||

| Ni | Cr | Fe | Mn | C | Cu | Si | S | P | Co | Nb/Cb | Ti | Ta | Al | Mo | B | Pb | Bi | Se | |

| Alloy 600 | >=72 | 14-17 | 6-10 | 1 | 0.1 | 0.5 | 0.5 | 0.015 | 0.04 | 1 | 1 | 0.5 | 0.05 | 0.35 | - | ||||

| Alloy 601 | 58-63 | 21-25 | bal | 1 | 0.1 | 1 | 0.5 | 0.015 | - | - | - | - | - | 1-1.7 | - | ||||

| Alloy 625 | >=58 | 20-23 | 5 | 0.5 | 0.1 | 0.5 | 0.5 | 0.015 | 0.015 | 1 | 3.15-4.15 | 0.4 | 0.05 | 0.4 | 8-10 | ||||

| Alloy X750 | >=70 | 14-17 | 5.0-9.0 | 1 | 0.08 | 0.5 | 0.5 | 0.01 | - | 1 | 0.7-1.2 | 2.25-2.75 | 0.05 | 0.4-1.0 | - | ||||

| Alloy 718 | 50-55 | 17-21 | bal | 0.35 | 0.08 | 0.3 | 0.35 | 0.015 | 0.015 | 1 | 4.75-5.5 | 0.65-1.15 | 0.05 | 0.2-0.8 | 2.8-3.3 | 0.006 | 0.0005 | 0.00003 | 0.003 |

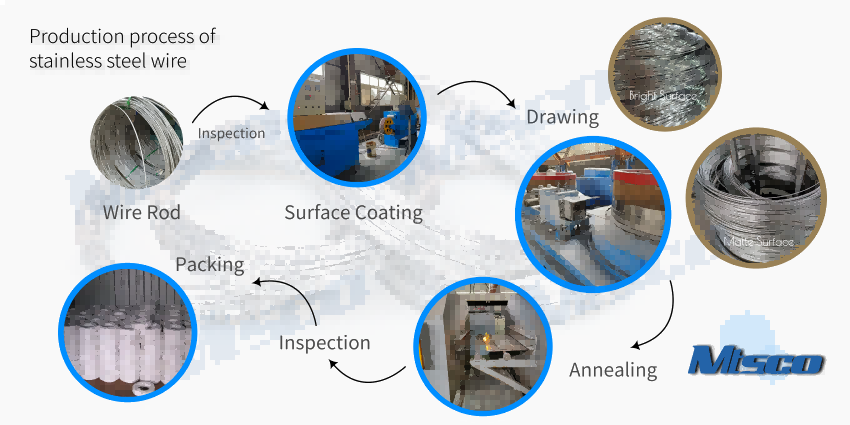

Production process of stainless steel wire:

Application:

Quality Control

Why Choose MTSCO?

Factory Complex

Provide you with cost-effective products and professional services.

One stop procurement of wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 18 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.

English

English Español

Español Русский

Русский عربي

عربي